Introduction:

The Honey Bottling Machine is a versatile, high-performance solution designed to efficiently fill honey, thick pastes, and mayonnaise into containers at speeds of 1-50 bottles per minute. Crafted with food-grade stainless steel, it ensures hygiene and durability, while its adjustable settings accommodate diverse bottle sizes (10ml to 5L) and viscosities. Key features include precision filling to minimize waste, an intuitive touchscreen interface for easy operation, and a compact design suitable for small workshops or large production lines. By automating the bottling process, it boosts productivity, reduces labor costs, and maintains consistent product quality. Ideal for food manufacturers, artisans, and startups, this machine offers unmatched reliability, scalability, and a rapid ROI—empowering businesses to meet growing demand while upholding industry standards.

Shipping:

Support Sea freight

Place of Origin:

Shanghai, China

Payments:

L/C,D/A,D/P,T/T,Western Union,MoneyGram,OA

Lead time(days):

1-1(acres):15(days),>1(acres):To be negotiated(days)

Product detail

Containers | Bottle,Jerry Can ,canister,Tin,Pail, Drum,IBC,etc. | Video outgoing-inspection | Provided |

After-sales Service Provided | Video technical support, Online support | Place of Origin | Shanghai, China |

Driven Type | Electric | Brand Name | GLZON |

Filling Accuracy | 99.9% | Machinery Test Report | Provided |

Product Characteristics:

1.High-Quality Food-Grade Materials - Crafted from premium food-safe materials for durability, hygiene, and honey purity;

2. Customizable Bottle Sizes - Adaptable to diverse container dimensions for flexible packaging solutions;

3. Precision Dosing System - Ensures accurate filling, minimizes product loss, and maximizes efficiency;

4. Anti-Drip Nozzles & Spill-Proof Seals - Prevent leaks and spills for a mess-free bottling process;

5. User-Friendly Interface - Intuitive controls enable seamless operation and rapid adjustments to boost productivity.

Product Applications:

The applications of the Honey Bottling Machine are extensive and vital in the honey industry. Honey producers, both large and small-scale, rely on these machines to ensure consistent filling and packaging, maintaining the quality and purity of their products. Health food stores, supermarkets, and specialty stores benefit from the beautifully bottled honey, enhancing the visual appeal of their shelves. Additionally, these machines are crucial for honey-based product manufacturers, supplying them with precisely filled containers for a variety of goods such as honey-infused sauces, cosmetics, and medicinal products. The versatility of these machines extends to various floral honeys, allowing producers to showcase the unique flavors of different regions.

APPLICABLE BARREL TYPE

COMPANY PROFILE

Shanghai Guangzhi Automation Equipment Co., Ltd. is a production and trading company specializing in the weighing industry. We are located in Shanghai, China's economic city, with convenient transportation and export ports all over the world. We cooperate with state-owned factories and international companies, and the quality is guaranteed.

We mainly focus on providing customers with weighing solutions, from commercial scales to industrial weighing machines. Such as pneumatic valve bag packaging machine, dry mix mortar bag packaging machine, cement packaging machine, natural stone powder packaging machine, flour powder packaging machine, wheat packaging machine, potato starch packaging machine, air packaging machine, granule bag packaging machine, grain packaging machine, fertilizer bag packaging machine, lubricant filling machine, 200 kg drum filling machine, 216L drum filling machine, 208L drum filling machine, ton barrel filling machine, IBC barrel filling machine, jumbo bag packaging machine, ton bag packaging machine, 30L pail filling machine, 50L pail asphalt filling machine, ATEX barrel filling machine, explosion-proof filling machine, etc.

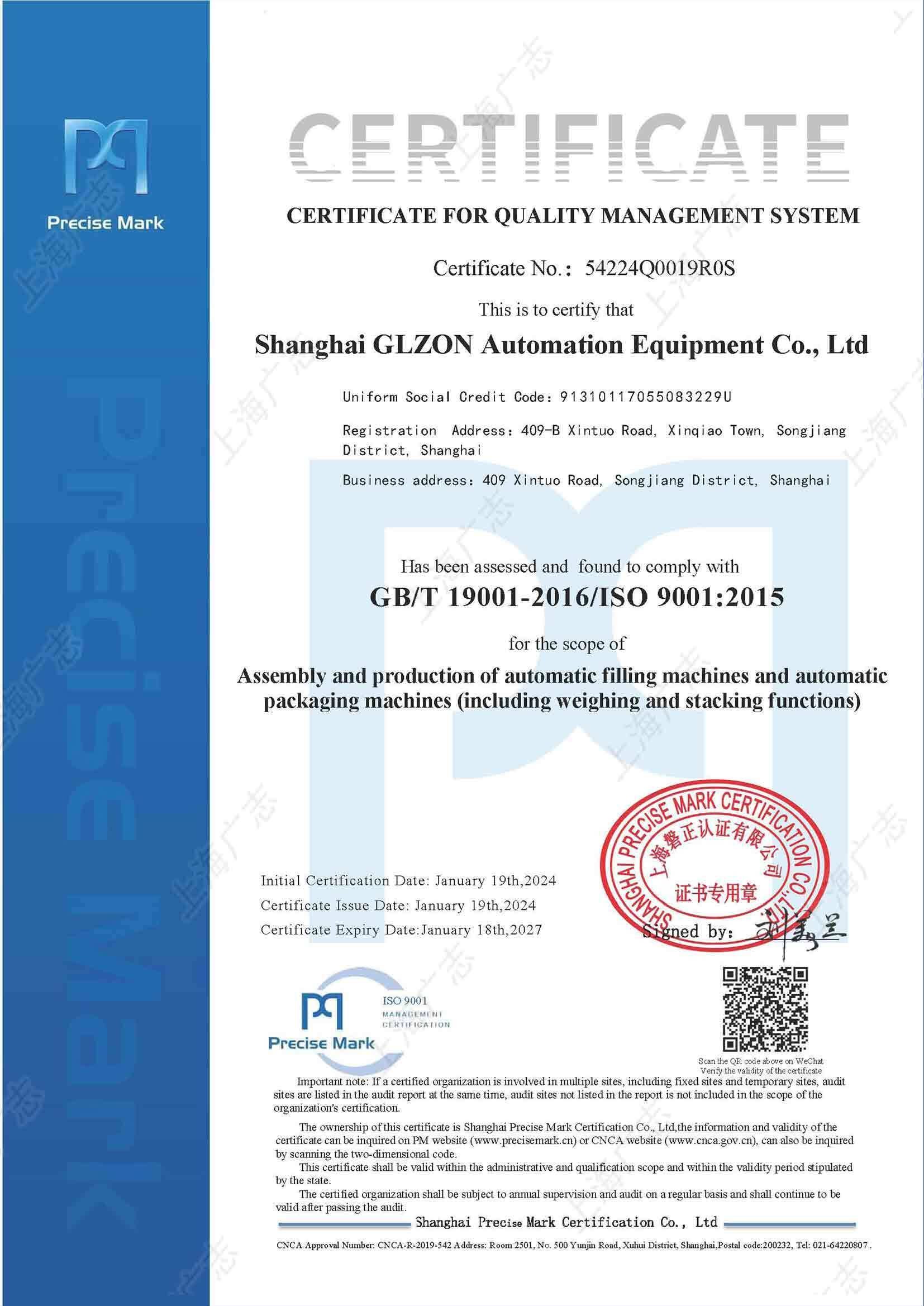

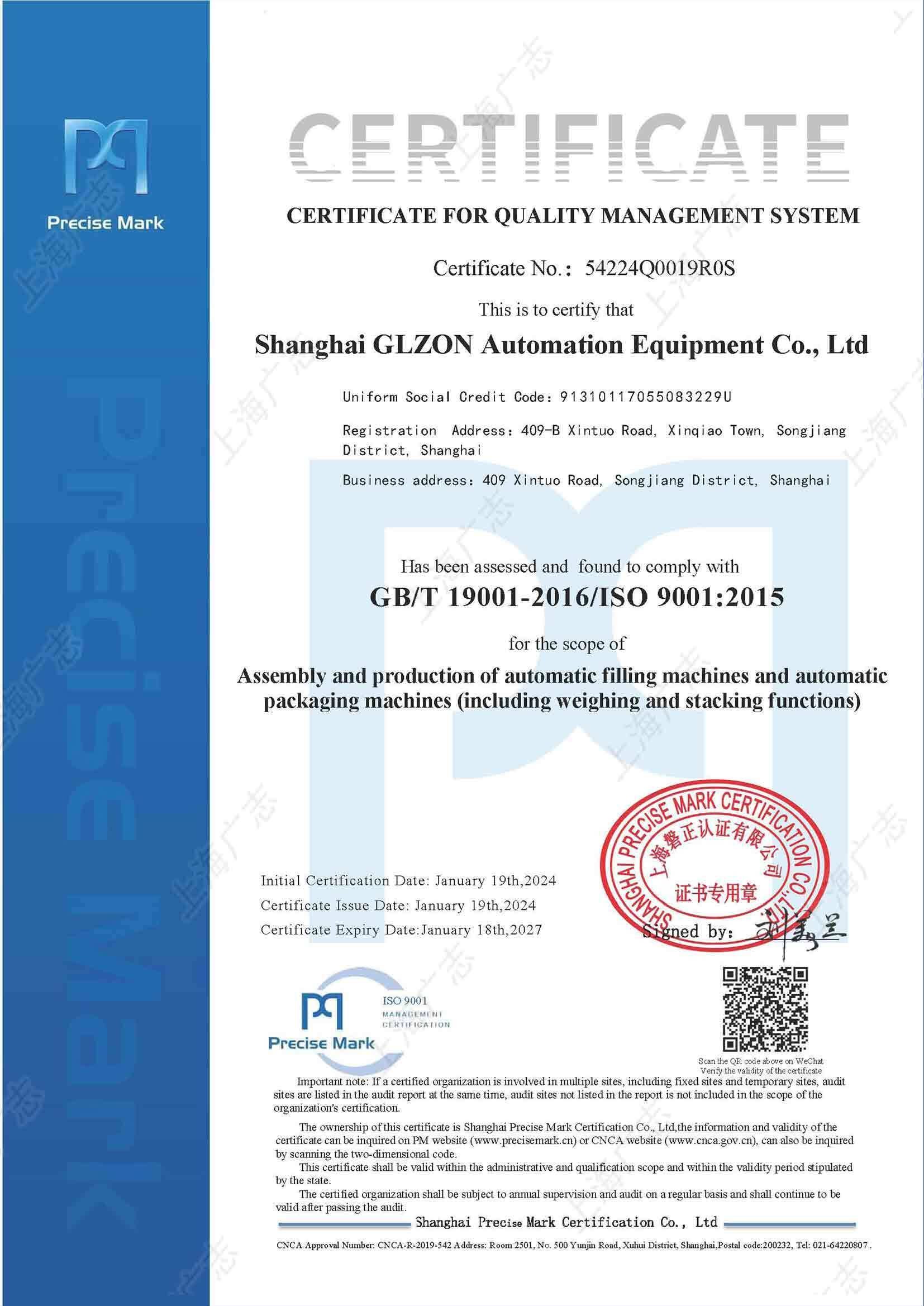

Company Certificate

Our office and workshop

Consulting-Design-Procurement-Processing-Production-Installation-Debugging-Training-Maintenance

This is a partial

service for us

in China.

Over 30 years of experience, every time we produce in

Shanghai, our friends can visit our factory at any time.

Brand components

We will ensure that our company's equipment has safety, stability, high efficiency and intelli-gent technology, so as to meet your needs, we can also cooperate with you in selecting in-ternational product brand production and business.

Our service

Complete solution provided

Telephone exchange joint business design plan, you can also visit our company ; we have a good environmental office vehicle,you can visit from time to time.

Duty after death

Our music team has a strong heart, and the customer's suspicions are also the purpose 24 hours of phone cell service and listing to the conversation at any time.

Technology group

We have a wealth of technical personnel and our technical team has been developing technical skills for over ten years.

Successful collaboration

Our factory in Shanghai. China provides free training for our technical staff.Better guarantee good product safety , our company provides safety, convenience, high efficlency packaging servic.

packge and delivery

Multiple Transportation way :Express(Fedex/DHL/TNT/EMS/UPS etc),air and shipping for your choose

Our in-house designers and engineers have produced countless great designs for customers from different industries

1

Can we get your free samples?

Samples can be offered for free. But courier cost for the samples should be at buyer's account.

2

Can you print our LOGO in flatware set?

Yes.we can print the logo on the flatware set as your requirements.Embossed, laser,stamped and engraved are available.

3

How long is the delivery time of sample?

Samples from stock can be sent within 1-3 days. New produced samples will be sent within 5-15 days.

4

Is there any MOQ for what I purchase?

Yes, we have MOQ for mass production. Different item with different package has different MOQ. Please contact us for more details.

5

Do you accept OEM or ODM services?

OEM and ODM are accepted!

6

What is 18-10 Stainless Steel Flatware?

18-10 refers to the composition of stainless steel. It contains 18% chromium and 10% nickel for excellent strength and corrosion resistance.